Benefits

- Many standard components

- Short cycle times

- Maximum output through shortest auxiliary times (only rotary table time + short axis travel)

- No docking necessary due to fixed table clamping

- Up to 4 workpieces simultaneously for even higher output (dependent on workpiece accuracy)

- Optional-parallel multi-side machining

Technical Highlights

- Clamping devices are permanently connected to the rotary table (no docking)

- The rotary table axis is horizontal

- Multiple clamping possible, allowing for high production quantities up to about 10 million

- Use of more than just one tool (axis unit) per station possible

- (for example, 2 operations are performed simultaneously on the same workpiece)

- Use of many standard components possible (axis units, spindle units, base, cover, platform...)

- Many variations and combinations possible (e.g., orientation of axis units + spindle units vertically and horizontally)

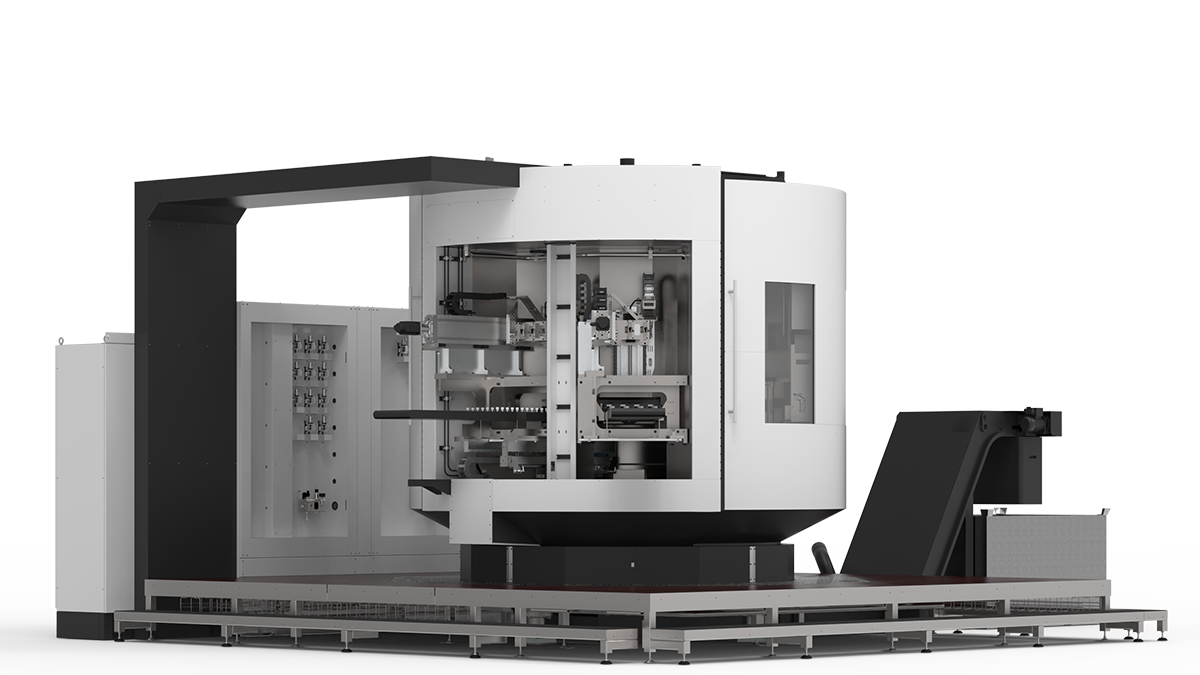

MT-40-X

| Machining Space | Approximately 100*100 |

| Workpiece Material | Steel, Aluminum, Non-Ferrous Metal |

| Stations | 6-12 |

| Clamping Devices | 3-Jaw Chuck, Center Clamping, Collet Chuck + Multiple Clamping Systems |

| Machining | Milling, Drilling |

| Loading | Robot, Bar Magazine, Manual |

| Rotary Table | Torque Table including Highly Precise Angle Measurement System and Hydraulic Clamping |

| Rotary Units/4th Axis (Optional | Integrated in the Rotary Table, up to 10,000 rpm (including clamping) |

| Spindles | HSK-32/40/50, Crown Revolver, Motor Spindle, and more |

| Frame Structure | Steel Welded Construction + Cast Construction, Rotary Table and Spindles Cooled |

| Standard Modules | 3-axis, 2-axis, Feed Slide, Turning Module, Cleaning Station or Special Units |

| Control | SIEMENS ONE, Fanuc |

| Options | e.g., Integrated Workpiece Measurement System with Data Feedback into the Manufacturing Process |

MT-60-X

| Machining Space | Approximately 200*200 |

| Workpiece Material | Steel, Aluminum, Non-Ferrous Metal |

| Stations | 8-12 |

| Clamping Devices | 3-Jaw Chuck, Center Clamping, Collet Chuck |

| Machining | Milling, Drilling |

| Loading | Robot, Bar Magazine, Manual |

| Rotary Table | Torque Table including Highly Precise Angle Measurement System and Hydraulic Clamping |

| Rotary Units/4th Axis (Optional | Integrated in the Rotary Table, up to 10,000 rpm (including clamping) |

| Spindles | HSK-50/63, Crown Revolver, Motor Spindle, Planetary Rotary Units, and more |

| Frame Structure | Steel Welded Construction + Cast Construction, Rotary Table and Spindles Cooled |

| Standard Modules | 3-axis, 2-axis, Feed Slide, Turning Module, Cleaning Station or Special Units |

| Control | SIEMENS ONE, Fanuc |

| Options | e.g., Integrated Workpiece Measurement System with Data Feedback into the Manufacturing Process |

MT-100-X

| Machining Space | Approximately 600*600*500 |

| Workpiece Material | Steel, Aluminum, Non-Ferrous Metal |

| Stations | 4 - 8, Single or Double Clamping |

| Clamping Devices | Special Clamping Devices of All Types (Swivel Clamps, Toggle Clamps, Centering) |

| Machining | Plan Slide Machining, Drilling, Milling |

| Loading | Robot, Bar Magazine, Manual |

| Rotary Table | NC-Hydraulic with Hirth Gear with or without NC Planetary |

| Number and Design of Planets/Stations | Individual (with Division or Stepless) |

| Spindles | HSK-63/80/100, Multi-Spindle Heads, Crown Revolver, Plan Slides Multiple spindles can be used per station! |

| Space Requirement | Base Machine: Ø5.2m + Periphery (Arrangement Individual) |

| Control | SIEMENS ONE (Other controls available on request) |