Deburring

Deburring Solutions

Requirements concerning the workpiece and its edges are increasing and therefore the deburring process is becoming progressively more important. Until some time ago, deburring was considered as an unaddressed necessary “evil”, but today it is getting more and more essential to manufacture burr-free workpieces.SEMA offers many years of experience with countless implemented applications – our deburring team is specialised in finding the perfect deburring process for each request.

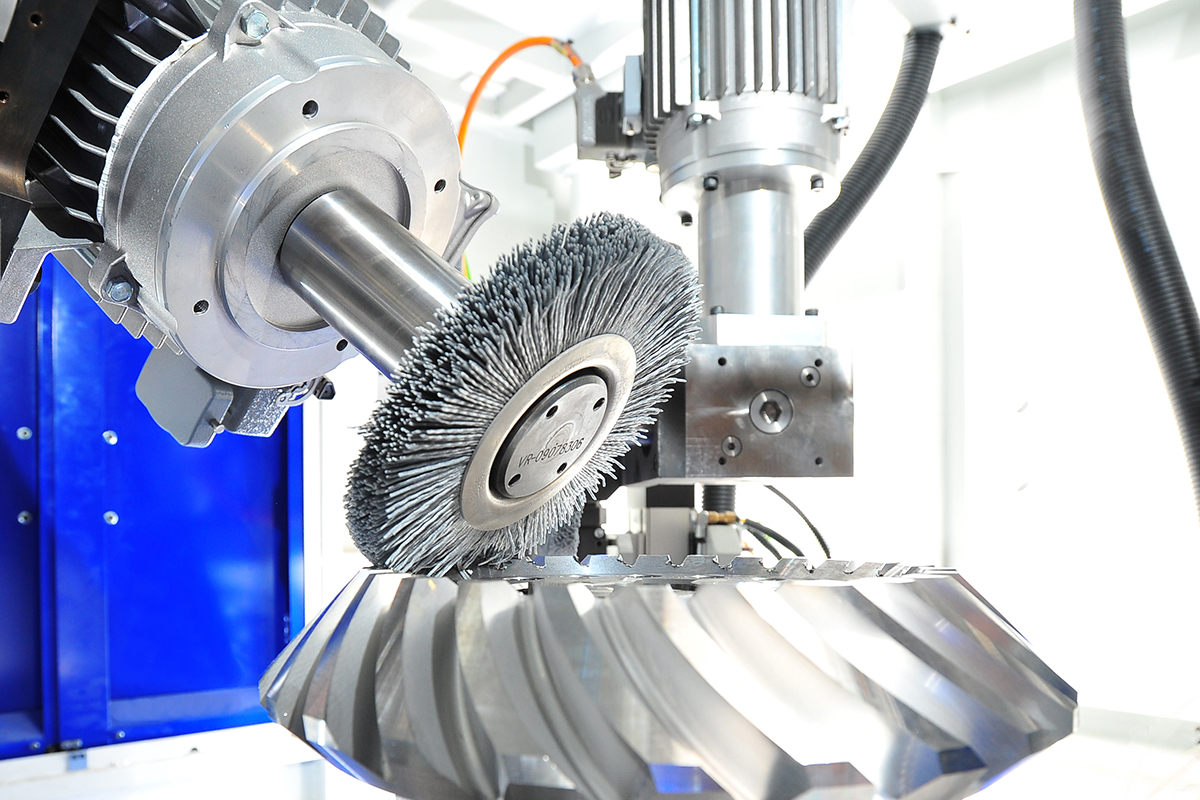

Deburring brush

In various sizes, made of steel or plastic, for deburring easy accessible edges. The control unit automatically compensates attrition. The brushes are clamped into the machine through a quick change system.

Internal deburring brush

Internal deburring by brush. To compensate attrition, new brushes are supplied from a magazine. If the internal diameter is bigger, the attrition can also be corrected automatically by the control unit.

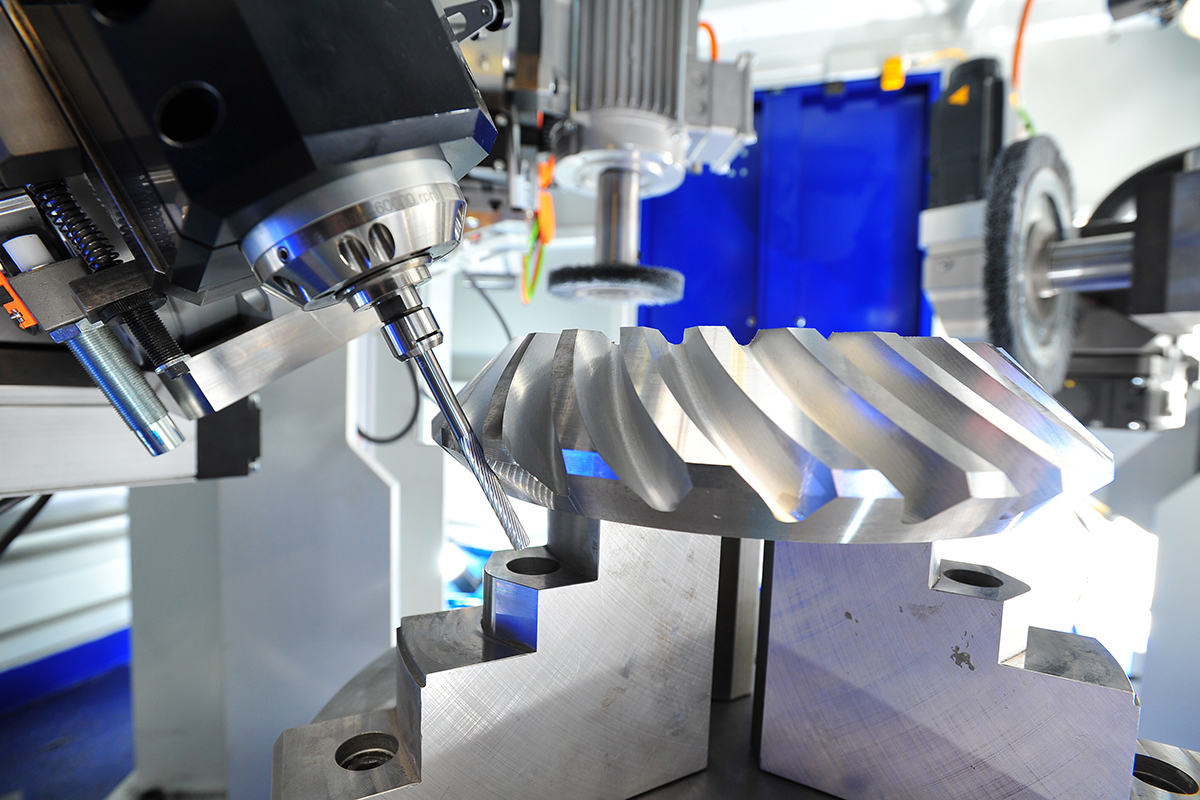

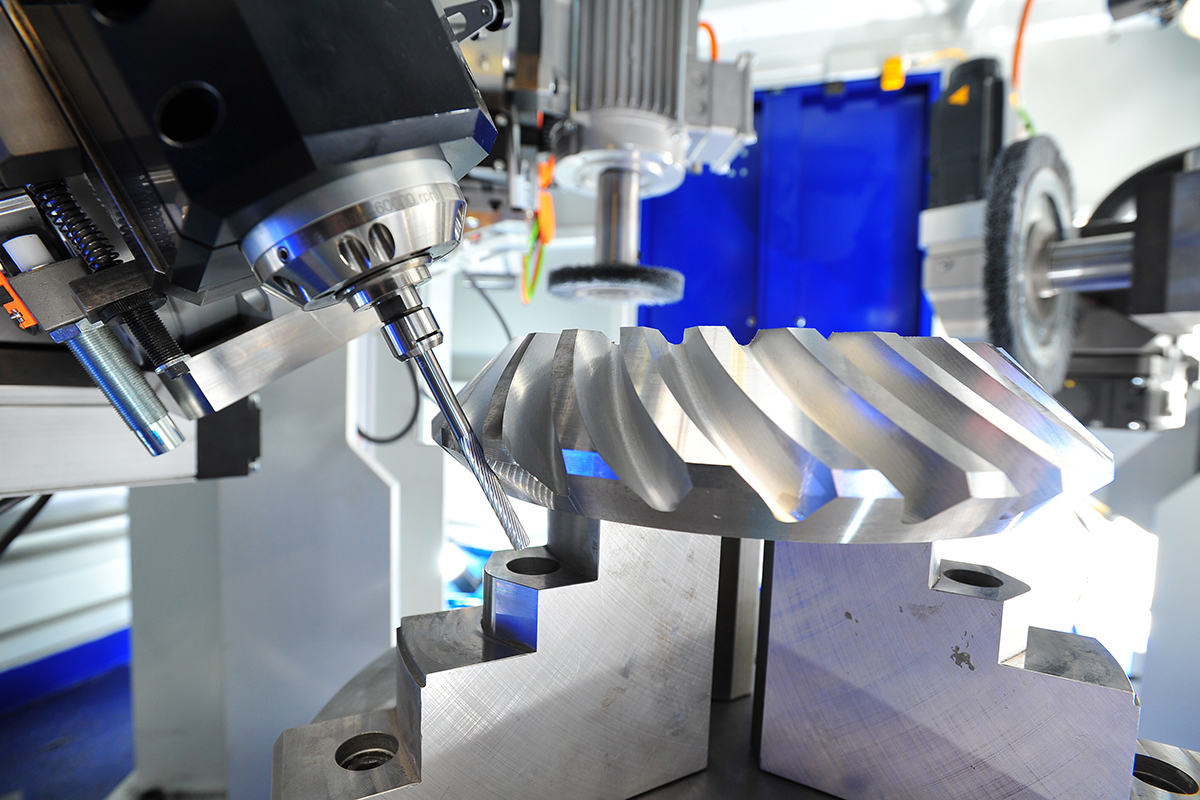

Burr

For initial deburring of gearings and removal of large primary burrs. The burr is inserted into an electric high-frequency milling spindle and is therefore able to work at various speeds. The burr follows the gearing or can be specifically placed at an edge that needs deburring.

Planetary deburring heads

For deburring of faces. The planetary deburring head is equipped with 4 disc brushes which counter-rotate. This ensures a consistent deburring of the whole face. The control unit automatically compensates attrition.

Grinding discs

For grinding faces and curves, for improving the surface, or for preparing for the following process, e.g. brushing or polishing.

Rotary Transfer Deburring

The rotary transfer machines can be equipped with 2 to 12 stations. The first station is always the workpiece clamping position. The other stations can be equipped with various machining units, such as: milling spindle, planetary deburring head, turning device, brush unit, etc. The rotary table is situated in the middle of the machine. The individual clamping mechanisms for the workpieces are mounted to this. This Machine enables as short as possible cycle times.

End Deburring Machine

The machines are designed for longer workpieces up to a maximum length of 2,500 mm. The workpieces are clamped between two tips, with one tip on the drive side and the counter-tip following. Depending on the machining required, several different machining units can be mounted in this case as well.

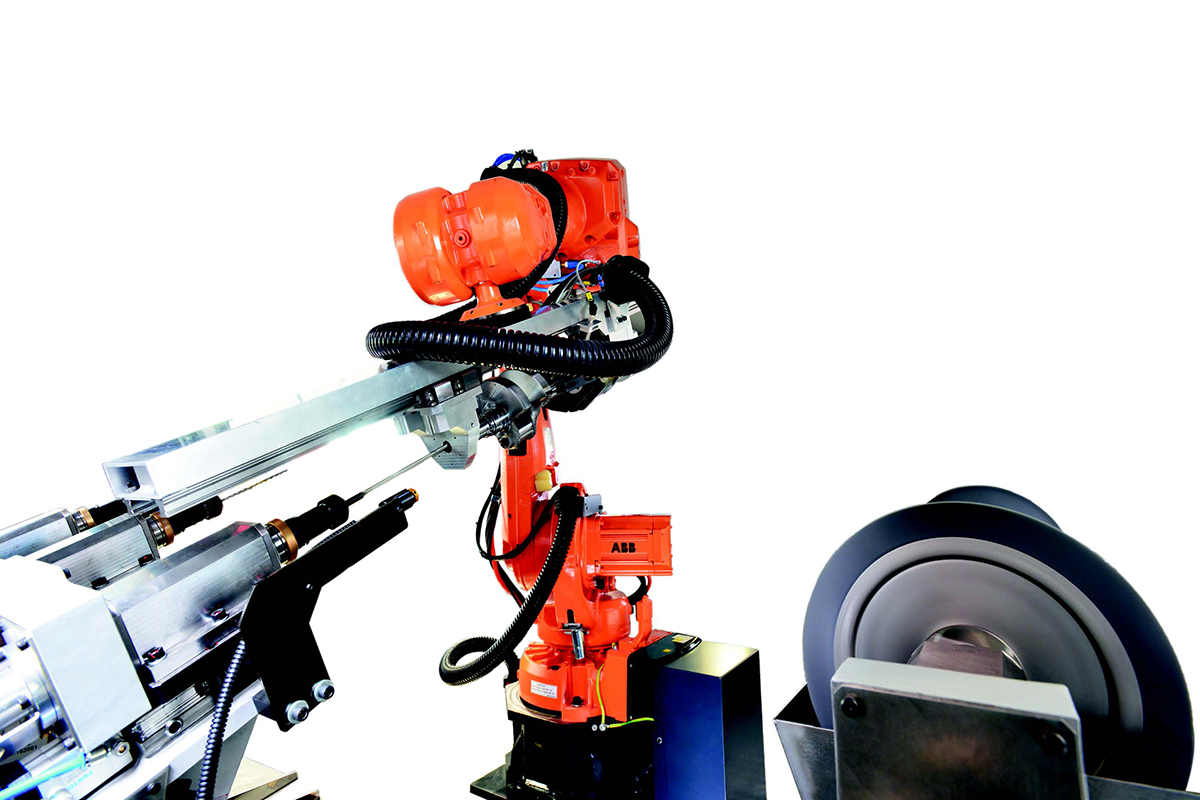

Flexible Deburring Machine

These deburring machines are equipped with a robot for handling either the workpieces or the tools. This choice depends mostly on the part size or the number of machining tools. The robot cells are completely covered so that the cell can be connected to an external vacuum system.

Custom Deburring Machine

These machines have been designed for larger workpieces with a maximum workpiece diameter of 800 mm. The central tool clamping spindle is situated in the centre of the machine.The individual machining units are installed around the outside of the workpiece spindle. The machining units are mounted to NC feed axes (1-axis, 2-axis, 3-axis or 4-axis). Depending on the machining requirements, various machining units can also be used here.